Product

News

- Future development trend of pellet activated carbon

- The main differences between coconut shell activated carbon and coal-based activated carbon in application

- Comparison and application analysis of graphitized petroleum coke and calcined petroleum coke

- Application of Activated Carbon in CO2 Purification

contacts

Contacts:Janice Zhang

Phone:18039276615

Email:Janice.dfxingguang@outlook.com

Address:Zhangjiamen Village, Dengfeng City, Henan Province

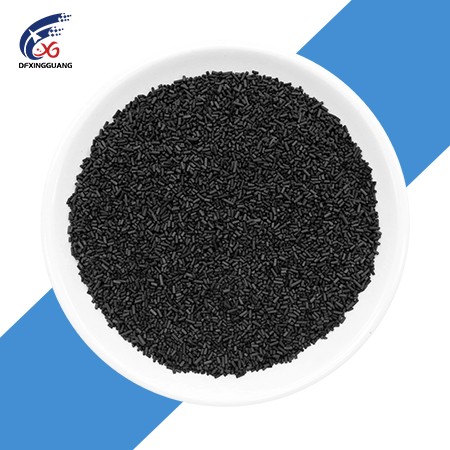

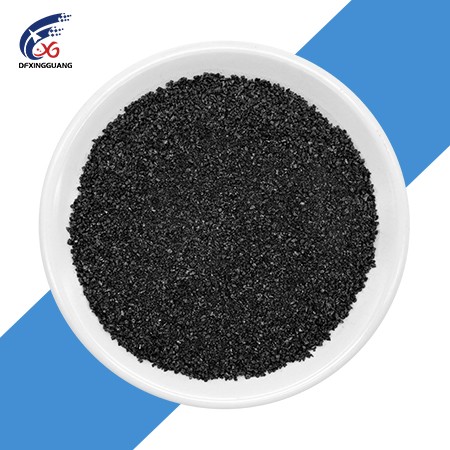

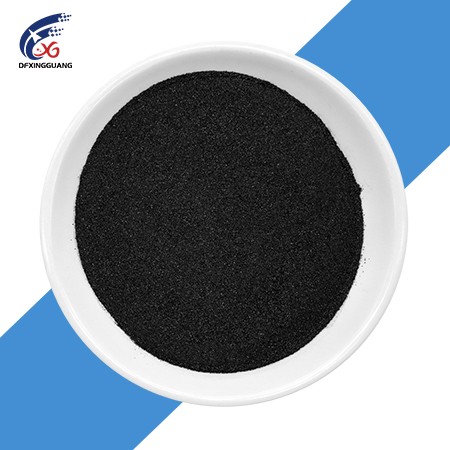

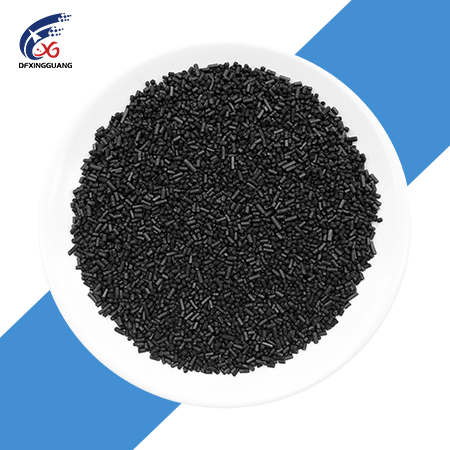

Pellet Activated Carbon

Pellet Activated Carbon

Description:

Pellet activated carbon is made of high-quality coal or wood raw materials through crushing, mixing, extrusion molding and high-temperature activation processes. It has the characteristics of regular cylindrical appearance (diameter 1.5-4mm), high strength, low pressure resistance, etc. It is specially designed for continuous flow systems such as industrial waste gas treatment (VOCs purification), flue gas desulfurization and denitrification, and coal gas purification. It is an ideal choice for environmental protection engineering and chemical industry.

Features:

✅ High strength: wear-resistant, crush-resistant, not easy to powderize after long-term use (strength ≥ 95%).

✅ Low pressure resistance: regular columnar structure, small airflow resistance, energy saving.

✅ High adsorption capacity: iodine value ≥ 800mg/g, carbon tetrachloride adsorption rate ≥ 50%.

✅ Economical and durable: renewable and reusable, reducing operating costs

Technical Data Sheet:

|

Parameter |

Unit |

Specifications |

|

Pellet Diameter 4.0±0.3mm, passing |

% |

95 min. |

|

Iodine Number |

mg/g |

800-1200 min |

|

CTC Adsorption |

% |

40-60 |

|

Ash content |

% |

12.0 max. |

|

Bulk Density |

g/l |

520 – 600 |

|

Hardness |

% |

95 min. |

|

Moisture Content |

% |

5.0 max. |