Product

News

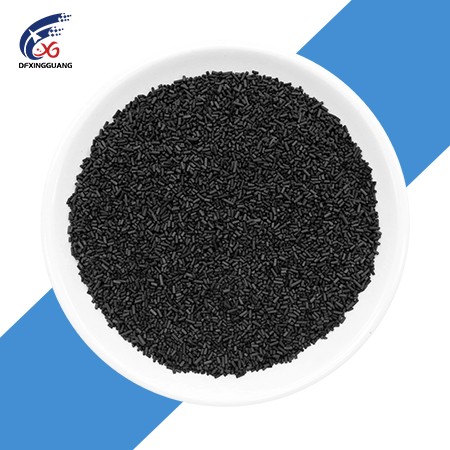

- Future development trend of pellet activated carbon

- The main differences between coconut shell activated carbon and coal-based activated carbon in application

- Comparison and application analysis of graphitized petroleum coke and calcined petroleum coke

- Application of Activated Carbon in CO2 Purification

contacts

Contacts:Janice Zhang

Phone:18039276615

Email:Janice.dfxingguang@outlook.com

Address:Zhangjiamen Village, Dengfeng City, Henan Province

News

The main differences between coconut shell activated carbon and coal-based activated carbon in application

- Raw materials and structural differences

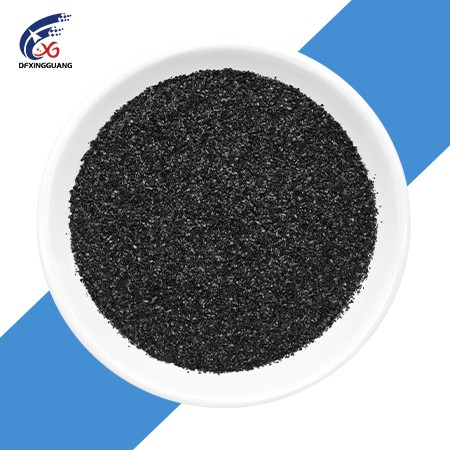

Coconut shell activated carbon is made from coconut shells and activated by high-temperature carbonization. It has the characteristics of well-developed micropores and large specific surface area (1000-1500 m²/g), and is better at adsorbing small molecular gas and liquid impurities.

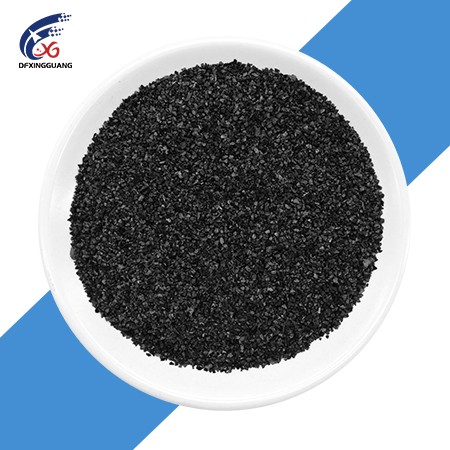

Coal-based activated carbon is made from anthracite or lignite, has a wider pore distribution (including macropores, mesopores and micropores), high mechanical strength, and is suitable for high-intensity industrial environments.

- Comparison of main uses

(1) Coconut shell activated carbon - high-precision adsorption

Drinking water purification: removal of residual chlorine, organic pollutants, and odors (such as household water purifiers and bottled water treatment).

Food and medicine: decolorization of sugar solution and purification of drugs (in compliance with FDA standards).

Gold extraction: adsorption of precious metals such as gold and silver in solution (CIP process).

High-end air purification: adsorption of small molecular VOCs such as formaldehyde and benzene (such as air purifier filters).

Advantages: low ash content, high purity, suitable for fields with strict hygiene requirements.

(2) Coal-based activated carbon - industrial-grade treatment

Industrial wastewater treatment: adsorption of dyes, heavy metals (such as electroplating wastewater) and macromolecular organic matter.

Waste gas treatment: VOCs recovery, flue gas desulfurization (such as chemical and petrochemical industries).

Catalyst carrier: used for synthetic ammonia and petrochemical catalytic reactions (due to high temperature resistance and high strength).

Wastewater treatment plant: used for post-biochemical deep treatment (low cost, suitable for large-scale application).

Advantages: low price, high strength, suitable for high flow and high pollution load scenarios.

- How to choose?

High purity requirements (food, medicine, drinking water) → select coconut shell activated carbon.

Industrial-grade treatment (wastewater, waste gas, catalysis) → select coal-based activated carbon.

Cost-sensitive projects → give priority to coal-based activated carbon.

Conclusion

Due to the different raw materials and pore structures, coconut shell activated carbon and coal-based activated carbon have different focuses in their application fields. Coconut shell charcoal is better at high-precision adsorption, while coal-based charcoal is better at industrial-scale applications. Users can choose the most economical solution based on their specific needs.

-

2025-07-08 01:01:36

Future development trend of pellet activated carbon

-

2025-07-04 23:48:17

Main uses and development prospects of alumina powder

-

2025-06-15 23:47:11

Advantages and development prospects of graphitized petroleum coke