Product

News

- Future development trend of pellet activated carbon

- The main differences between coconut shell activated carbon and coal-based activated carbon in application

- Comparison and application analysis of graphitized petroleum coke and calcined petroleum coke

- Application of Activated Carbon in CO2 Purification

contacts

Contacts:Janice Zhang

Phone:18039276615

Email:Janice.dfxingguang@outlook.com

Address:Zhangjiamen Village, Dengfeng City, Henan Province

Knowledge

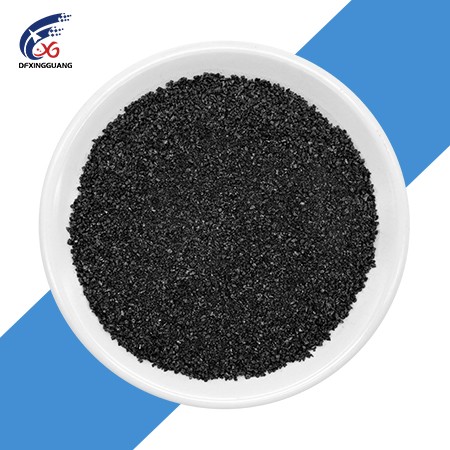

Key material for gold extraction – coconut shell gold extraction activated carbon

In the gold smelting and recovery industry, activated carbon has become an indispensable material due to its excellent adsorption performance, especially in the "carbon-in-pulp (CIP)" and "carbon-in-leach (CIL)" processes. Gold extraction activated carbon is prepared by physical or chemical activation method, with high specific surface area, developed pore structure and strong adsorption capacity, which can efficiently adsorb gold cyanide complex ([Au(CN)₂]⁻) in the slurry, thereby improving the gold recovery rate.

- Characteristics requirements of gold extraction activated carbon

High adsorption capacity: The gold loading of high-quality gold extraction activated carbon needs to reach 10-15 kg/t (10-15 kg of gold adsorbed per ton of activated carbon), and the pores are mainly 2-5 nanometers of mesopores, which are conducive to the diffusion and adsorption of gold cyanide complexes.

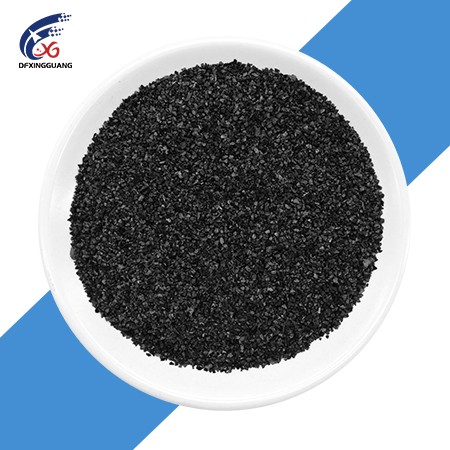

High strength and wear resistance: It needs to withstand mechanical wear in the stirred slurry to avoid breakage and loss of gold powder. Coconut shell or apricot shell is usually used as raw material, and its hardness is better than coal-based activated carbon.

Low impurity content: Metal impurities such as calcium and iron may interfere with the adsorption process, and the ash content needs to be reduced to ≤3% through acid washing pretreatment.

- Production process and classification

Raw material selection: Coconut shell activated carbon is the first choice because of its uniform pores and high strength. Coal-based activated carbon has a lower cost but needs to optimize the pore size distribution.

Activation process:

Physical activation: high-temperature steam activation, environmentally friendly but time-consuming;

Chemical activation: phosphoric acid or zinc chloride activation, high efficiency but requires wastewater treatment.

Regeneration technology: Gold-loaded carbon can be reused 3-5 times after high-temperature calcination (750°C) or acid washing regeneration, reducing production costs.

- Industry applications and challenges

Gold-extracting activated carbon is widely used in mining and electronic waste recycling, and the global market size has an average annual growth of 5%-8%. However, the industry faces the following challenges:

Adsorption selectivity: Competing ions such as copper and zinc will occupy the pores of activated carbon, and surface modification technology (such as loading sulfide) needs to be developed to improve specificity.

Environmental protection requirements: tail gas (such as hydrogen cyanide) in the regeneration process needs to be strictly treated, and enterprises are encouraged to adopt closed-loop recycling systems.

- Future trends

With the decline in gold grades and stricter environmental regulations, the research and development of high-performance activated carbon has become a focus. For example, nanocomposites (such as graphene composite carbon) can increase the adsorption rate by more than 30%, while biomass-based activated carbon has attracted attention due to its renewable properties.

Conclusion

The technological progress of gold-extracting activated carbon is directly related to the benefits and sustainability of the gold industry. In the future, through material innovation and process optimization, activated carbon will play a greater role in the field of resource recovery.

-

2025-07-08 01:01:36

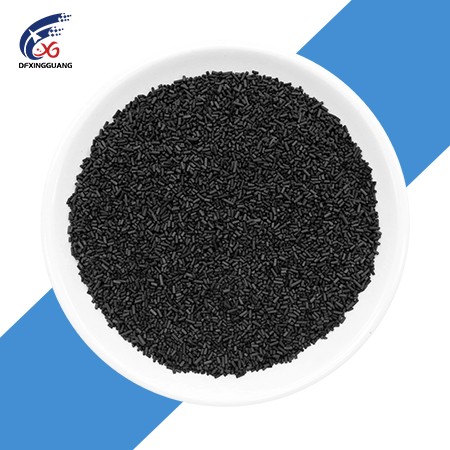

Future development trend of pellet activated carbon

-

2025-07-04 23:48:17

Main uses and development prospects of alumina powder

-

2025-06-15 23:47:11

Advantages and development prospects of graphitized petroleum coke