Product

News

- Future development trend of pellet activated carbon

- The main differences between coconut shell activated carbon and coal-based activated carbon in application

- Comparison and application analysis of graphitized petroleum coke and calcined petroleum coke

- Application of Activated Carbon in CO2 Purification

contacts

Contacts:Janice Zhang

Phone:18039276615

Email:Janice.dfxingguang@outlook.com

Address:Zhangjiamen Village, Dengfeng City, Henan Province

Knowledge

Differences and advantages and disadvantages of calcining bauxite in vertical kiln and rotary kiln

Calcination of bauxite is a key process for producing refractory materials and alumina. Vertical kiln and rotary kiln are two mainstream calcining equipment, which have significant differences in structure, energy consumption, product quality, etc., and are suitable for different production needs.

- Main differences

- Structure and working principle

Vertical kiln: vertical fixed kiln body, materials move from top to bottom, static calcination.

Rotary kiln: horizontal rotating cylinder, materials roll with the kiln body, dynamic calcination.

- Calcination temperature and uniformity

The temperature of the vertical kiln is generally ≤1600℃, which is suitable for medium and low-grade calcination, but the uniformity is poor;

The rotary kiln can reach 1800℃, the material is heated evenly, and it is suitable for high-grade calcination.

- Raw material adaptability

The vertical kiln requires block bauxite (10-50mm), and the powder is easy to clog;

The rotary kiln can handle powder or small particles (≤30mm), with high resource utilization.

- Capacity and energy consumption

The daily output of a single vertical kiln is 50-300 tons, with high thermal efficiency (75%) and low energy consumption;

The daily output of a single rotary kiln is 500-3000 tons, with low thermal efficiency (50%-60%) and high fuel consumption.

- Investment and maintenance

The vertical kiln has simple equipment, low investment and low maintenance cost;

The rotary kiln has a complex structure, high investment, but a high degree of automation.

- Advantages and disadvantages of vertical kilns

Advantages:

Low energy consumption, fuel cost is 20%-30% lower than that of rotary kilns;

Low investment, short construction period, suitable for small and medium-sized enterprises;

Easy maintenance, no rotating parts, low failure rate.

Disadvantages:

Poor calcination uniformity, easy to over-burn or under-burn locally;

Strict raw material requirements, block ore is required, and powder utilization rate is low;

Limited production capacity, difficult to meet large-scale production needs.

Applicable scenarios: small and medium-sized refractory plants, low-grade bauxite calcination.

- Advantages and Disadvantages of Rotary Kiln

Advantages:

High calcination quality, product active alumina content ≥ 85%;

Strong raw material adaptability, can process powdered or granular materials;

Large single-line production capacity, suitable for modern large-scale production.

Disadvantages:

High energy consumption, thermal efficiency is only 50%-60%;

Complex equipment, large investment, high maintenance cost;

Difficulty in waste gas treatment, high environmental protection investment.

Applicable scenarios: large alumina plants, high value-added refractory production.

- Development Trend

Vertical kiln: Improve thermal efficiency and uniformity by improving the kiln structure (such as double-chamber vertical kiln), and still be competitive in the small and medium-sized market;

Rotary kiln: Develop in the direction of intelligence and low energy consumption, and waste heat recovery technology (such as preheater + rotary kiln) can reduce energy consumption by 30%.

Conclusion

Vertical kiln and rotary kiln have their own advantages and disadvantages, and the selection needs to comprehensively consider the characteristics of raw materials, production capacity requirements and investment budget. In the future, with the upgrading of energy-saving technology, the two will complement and coexist in the field of bauxite calcination.

-

2025-07-08 01:01:36

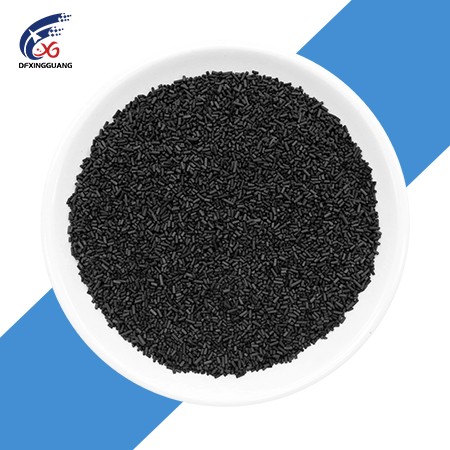

Future development trend of pellet activated carbon

-

2025-07-04 23:48:17

Main uses and development prospects of alumina powder

-

2025-06-15 23:47:11

Advantages and development prospects of graphitized petroleum coke