Product

News

- Future development trend of pellet activated carbon

- The main differences between coconut shell activated carbon and coal-based activated carbon in application

- Comparison and application analysis of graphitized petroleum coke and calcined petroleum coke

- Application of Activated Carbon in CO2 Purification

contacts

Contacts:Janice Zhang

Phone:18039276615

Email:Janice.dfxingguang@outlook.com

Address:Zhangjiamen Village, Dengfeng City, Henan Province

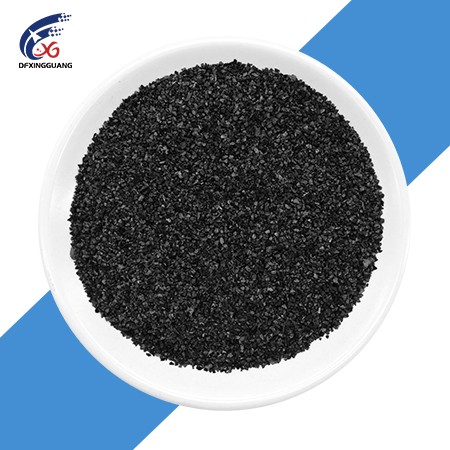

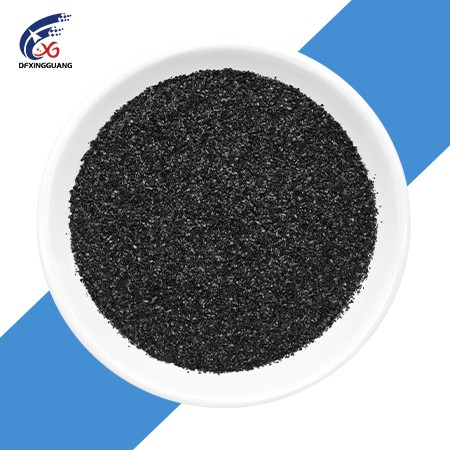

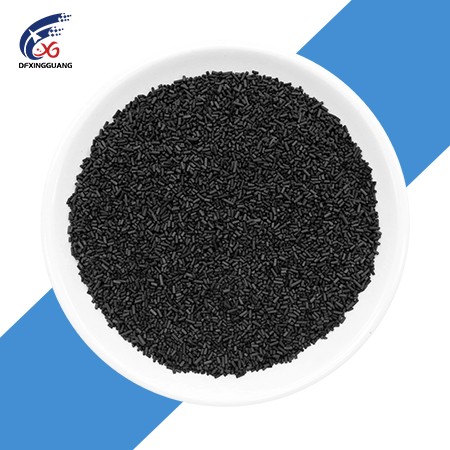

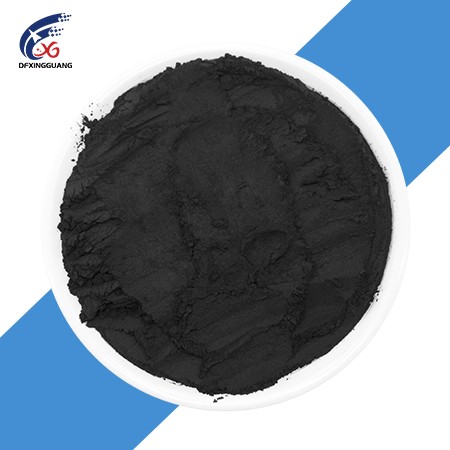

Silicon Carbide

Silicon Carbide

Description:

Silicon carbide (SiC) is a compound composed of silicon (Si) and carbon (C) and is a wide bandgap semiconductor material. It has key properties such as high hardness, high thermal conductivity, high melting point and stable chemical properties.

Application:

Silicon carbide (SiC) is made by high temperature smelting in a resistance furnace with raw materials such as quartz sand, petroleum coke (or coal coke), wood chips (salt is needed to produce green silicon carbide). Silicon carbide is widely used in electronics, wear-resistant materials and ceramics due to its excellent physical and chemical properties.

Grit No.

P series: P12-P2500

F series:F12-F1200

Refractory & Deoxidizer Series : 0-1,0-10,1-3,1-5,1-10 mm

Other series: Japanese standard “12-“6000

American standard12″-1200*

Technical Data Sheet:

|

Abrasives |

Grit Size |

Chemical Composition(%) |

|||

|

SIC(min) |

F.C(max) |

Fe2O3(max) |

|||

|

silicon carbide |

F12~F90 |

98.5 |

0.20 |

0.60 |

|

|

F100~F150 |

98.5 |

0.30 |

0.80 |

||

|

F180~F220 |

97.0 |

0.30 |

1.20 |

||

|

Refractory materials |

|

|

|||

|

0-1,0-10,1-3,1-10mm |

88-90 |

0.30 |

|

||

|

0.80 |

|||||

|

200mesh,325mesh |

98.0 |

0.30 |

1.50 |

||