Product

News

- Future development trend of pellet activated carbon

- The main differences between coconut shell activated carbon and coal-based activated carbon in application

- Comparison and application analysis of graphitized petroleum coke and calcined petroleum coke

- Application of Activated Carbon in CO2 Purification

contacts

Contacts:Janice Zhang

Phone:18039276615

Email:Janice.dfxingguang@outlook.com

Address:Zhangjiamen Village, Dengfeng City, Henan Province

Case

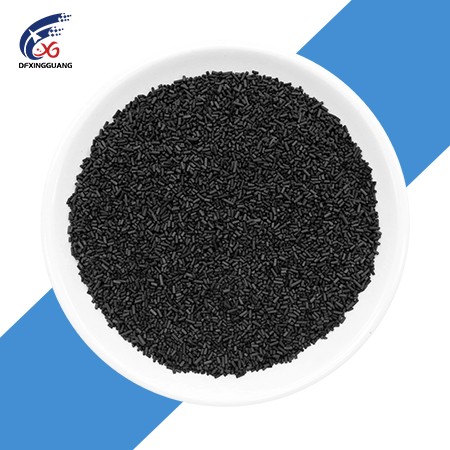

Application of pellet activated carbon in gas treatment

With the rapid development of industrialization and urbanization, air pollution is becoming increasingly serious. Harmful gases in waste gas (such as VOCs, hydrogen sulfide, sulfur dioxide, etc.) pose a serious threat to the environment and human health. As a high-efficiency adsorption material, pellet activated carbon plays an important role in the field of gas purification due to its high specific surface area, strong adsorption capacity, good mechanical strength and renewability. This article will introduce in detail the characteristics of pellet activated carbon, its application scenarios in gas treatment and its future development trends.

Application of pellet activated carbon in gas treatment

(1) Industrial waste gas treatment

Application industries: chemical, petroleum, pharmaceutical, coating, printing, etc.

Main pollutants: volatile organic compounds (VOCs) such as benzene, formaldehyde, acetone, and carbon disulfide.

Treatment method:

Adsorption tower process: The waste gas passes through the adsorption tower filled with pellet activated carbon, and VOCs are adsorbed and purified to meet the emission standards.

Combined process: Combined with catalytic combustion (RCO), biological filter and other technologies to improve treatment efficiency.

Case: A chemical plant uses a pellet activated carbon adsorption + nitrogen desorption regeneration system, with a VOCs removal rate of more than 95%, and an annual operating cost reduction of 30%.

(2) Flue gas desulfurization and denitrification (waste gas purification)

Application scenarios: coal-fired power plants, steel plants, waste incineration plants, etc.

Treatment targets: SO₂, NOx, mercury vapor, etc.

Technical advantages:

pellet activated carbon can adsorb SO₂ and NOx at the same time and convert them into harmless substances through catalytic reduction reactions.

Modified activated carbon (such as impregnated iodine or ammonia) can enhance the adsorption capacity of specific pollutants.

Case: A power plant uses activated carbon injection (ACI) technology, combined with SCR denitrification, to make SO₂ and NOx emissions lower than the national ultra-low emission standards.

(3) Indoor air purification

Application scenarios: homes, offices, hospitals, laboratories, etc.

Main pollutants: formaldehyde, benzene, ammonia, odor, etc.

Solution:

The air purifier has a built-in pellet activated carbon filter to absorb harmful gases.

The fresh air system is equipped with an activated carbon filter layer to improve air quality.

Advantages: Compared with powdered activated carbon, pellet activated carbon has lower wind resistance and is suitable for long-term use.

(4) Toxic gas protection

Application areas: gas masks, military protection, chemical emergency treatment, etc.

Adsorption targets: highly toxic gases such as chlorine, hydrogen sulfide, and hydrogen cyanide.

pellet activated carbon can be chemically modified (such as impregnated with metal oxides) to specifically absorb specific toxic gases.

Composite activated carbon filter canisters are commonly used in the military and firefighting fields to provide efficient protection.

-

2025-07-08 01:01:36

Future development trend of pellet activated carbon

-

2025-07-04 23:48:17

Main uses and development prospects of alumina powder

-

2025-06-15 23:47:11

Advantages and development prospects of graphitized petroleum coke